Getting My Digital Printing To Work

What Does Digital Printing Do?

Table of ContentsSome Ideas on Digital Printing You Need To KnowThe Only Guide for Digital PrintingA Biased View of Digital PrintingFascination About Digital PrintingThe Definitive Guide to Digital PrintingThe 6-Minute Rule for Digital PrintingThe 4-Minute Rule for Digital Printing

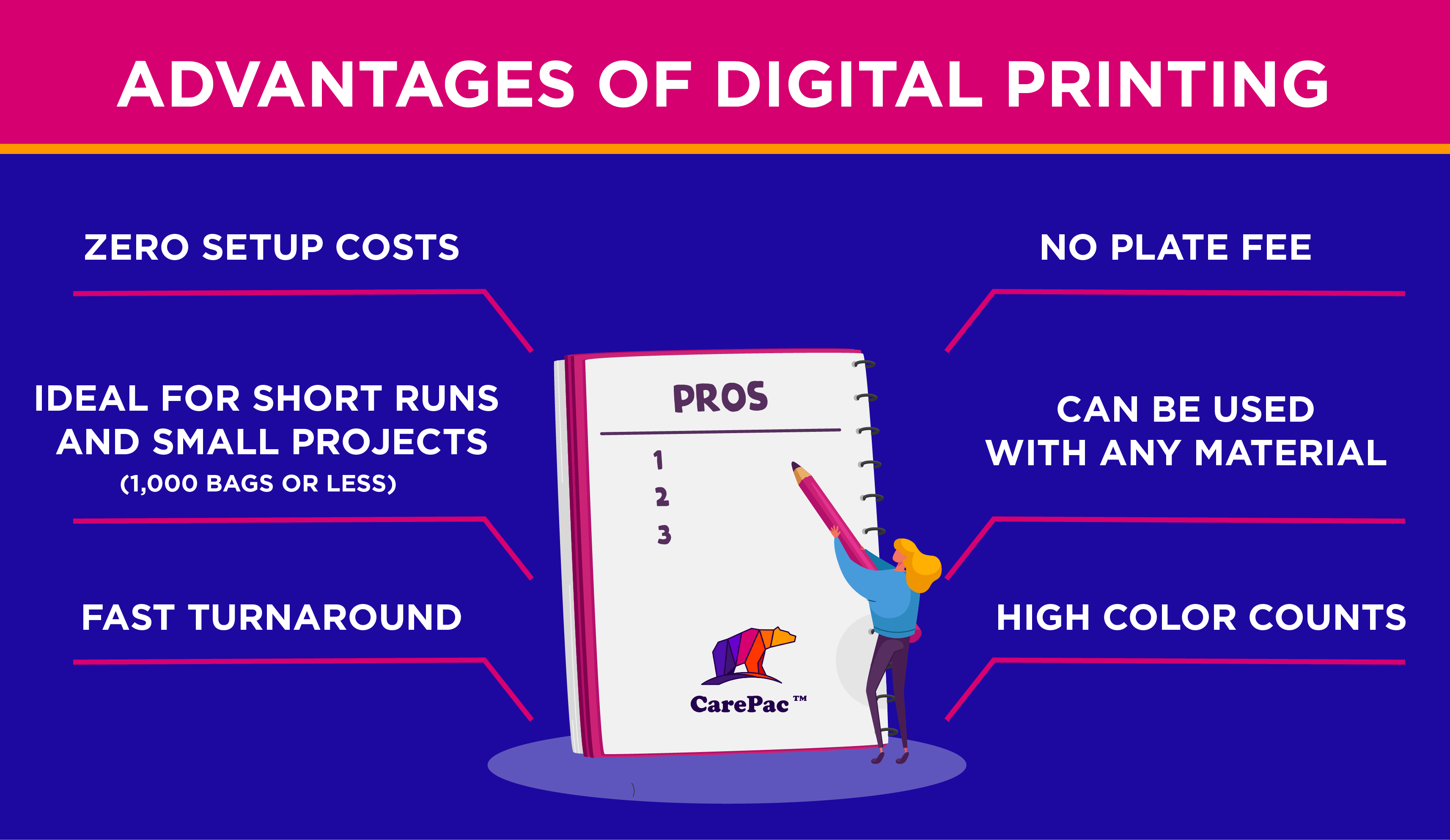

According to PMMI, electronic printing allows brands and makers to react rapidly to client demands while boosting the supply chain, reducing warehousing expense and waste, and appreciating faster time to market. That all sounds terrific, but exactly how does this modern technology do all that? The significant differentiator of these technologies is that there are no set-up fees and no plates with electronic printing.According to Wikipedia, the best difference in between electronic printing and traditional techniques such as lithography, flexography, gravure, or letterpress is that there is no requirement to change printing plates in electronic printing, whereas in these analog printing techniques home plates are repetitively replaced. This results in quicker turn-around time and reduces expense when utilizing electronic printing.

The Best Guide To Digital Printing

With standard printing methods, short-run printing is just not feasible. Due to the fact that a fantastic style can make or break your item, digital printing consistently develops high-grade, clear and vibrant graphics each time.

Digital printing is the process of printing digital-based images straight onto a range of media substrates. There is no demand for a printing plate, unlike with balanced out printing. Digital files such as PDFs or desktop publishing data can be sent out directly to the electronic printing press to publish on paper, picture paper, canvas, fabric, synthetics, cardstock and other substratums.

Digital printing is quicker and efficient in even more information, two factors it's usually utilized to print packaging, straight advertising leaflets, and publications or magazines. Many electronic printing machine have traditionally used toner-based technology and as that technology rapidly evolved, the print high quality measured up to that of offset presses. In the last few years, inkjet technology has streamlined electronic print ease of access in addition to the cost, speed and high quality obstacles facing print carriers today.

Digital Printing Fundamentals Explained

Balanced out printing is the suitable service when you need and/or flexible colour, paper and sizing alternatives. Digital Printing. Digital printing is ideal for jobs, normally less than 2,000 copies, and when you need a quick turnaround. So, if you are not exactly sure what's best for your job, we will certainly function with you to choose the print technique finest suited to your task and budget.

The exact color matching and adaptability it offers make it tough to neglect. Digital printing enables quick and economical manufacturing without compromising top quality, unlike balanced out printing. It enables smaller sized print runs and on-demand manufacturing, making it excellent for organizations of all sizes. Digital printing, with its remarkable color precision and uniformity, is a game-changer in the market.

While both have their merits, there are a number of my response vital differences that set them apart. Recognizing these differences can assist you make an enlightened decision regarding which approach is best suited for your printing requires. Countered printing has long been the go-to option for high-volume business printing. It entails transferring ink from plates to rubber blankets prior to ultimately using it onto the paper.

What Does Digital Printing Mean?

One notable benefit of offset printing machine is navigate to this site their capacity to take care of a vast array of paper sizes and densities. The countered press can fit numerous products, including glossy or textured papers, giving convenience that electronic printers may struggle to match. This printing technique relies upon the usage of printing plates to transfer the ink onto the paper, making it a popular selection for high-grade prints.

Changes may be necessary throughout the print run to preserve top quality consistency with printing presses. Digital printing, on the various other hand, uses a more structured approach contrasted to balance out press.

One considerable benefit of digital printing is the removal of costly configuration fees that are linked with countered printing. In traditional balanced out printing, each work requires the development of plates, which can be pricey and lengthy.

An Unbiased View of Digital Printing

An additional cost-saving facet of digital printing is the ability to print only what you require. Unlike countered printing, where huge amounts have to be generated to make the procedure financially sensible, electronic printers offer greater flexibility. Whether you call for a tiny set or a solitary copy, digital modern technology allows on-demand printing with no additional costs.

Making use of typical countered printing would certainly need producing a large amount upfront to attain an appropriate system expense per flyer. However, by choosing electronic printing rather, they can print only the specific number required at a lower overall cost.: A marketing company wants to run a direct-mail advertising project targeting different customer sectors with individualized brochures.

Among the essential advantages of next digital printing for fine print runs is its. Unlike offset printing, which needs the creation of plates and configuration time for every job, electronic printers can start creating prints nearly promptly. This makes them excellent for smaller quantities where time is of the essence.

The Single Strategy To Use For Digital Printing

One more benefit of electronic printing is its capability to produce tailored advertising and marketing products. With, organizations can easily incorporate personalized material within each printed piece.

One of the essential advantages is the boosted flexibility and modification alternatives that come with digital printing. With digital printing, making changes to designs or content during the production process is a wind. Unlike conventional balanced out printing, where making modifications can be lengthy and pricey, digital innovation enables fast and simple modifications.

Another benefit of electronic printing is its variable data capabilities. Whether you need to tailor each item with private names, addresses, or other one-of-a-kind info, variable data printing makes it feasible.

Not known Details About Digital Printing

Whether you're trying to find glossy or matte coatings, textured documents, or specialty stocks, electronic printers can accommodate numerous choices. This adaptability makes certain that your published materials straighten with your brand image while offering an aesthetically enticing end outcome. Digital printing truly radiates. The ability to customize layouts or content during manufacturing conserves time and resources compared to traditional balanced out approaches - Digital Printing.